Olive Trees and Olives

last update: 1 February 2021

I have always wondered about the myriad of bottles of olive oil you find on supermarket shelves. How to judge? How to know what is what? You will see later on this page a section entitled "Buying olive oil", but I still found it difficult to get to grips with the topic. Very recently I found out that since 1997 the Spanish government has funded an annual prize for the best extra virgin olive oil in Spain. They have three categories, bitter green fruity, sweet green fruity, and ripe fruity, as well as a special prize for the oil with the best score on the tasting and in the physical-chemical evaluation. My own preference for tasting is "bitter green fruity" which for 2019/2020 was won by Cortijo de Suerte Alta in Córdoba. My own personal preference for tasting is to dip a nice piece of fresh crusty bread into a little oil in a dish over which I've first sprinkled a little salt.

Introduction

Wikipedia is a mine of information of olives, which I have tried to summaries and expand on.

The name derives from Latin ŏlīva, and the word "oil" originally just meant "olive oil".

Botanical name for olives is Olea europaea, this is a species.

Olea is a genus of about 40 species in the family Oleaceae, and for us the most important species in the Olea is by far the olive (the olive is in fact the type species for the genes Olea).

More generally the family Oleaceae also includes ash, jasmine, lilac, …

There are six subspecies of Olea europaea, depending upon geographic area. We are interested in the Olea europaea subspecies europaea, which is found in the Mediterranean Basin. There are hundreds of cultivars (cultivated varieties) of olive trees, producing olives of quite different sizes, shapes, colours, growth, and of course producing quite different quantities and qualities of olive oil. Olive cultivars are very often named after their location of origin, but they can all be classed as either table olives for eating, or olives best for olive oil production, or both (duel-purpose). Some texts claim that there are more than 2,000 different cultivars of olives in the Mediterranean Basin alone.

There is a suggestion that given that olive wood burns also when humid, it was that characteristic that first attracted man. It's a big step to extracting oil from olives, but the fact that it can be used for cooking and it burns in lamps virtually smoke-free could have later emerged as its principle attractiveness. Olive pits and wood fragments have been discovered in tombs 19,000 year old. Wild olives were used for their oil possible as early as 7,000 to 10,000 years ago. Domesticated olives are said to have first appeared in the Near East, possible as early as 5,000 years ago. DNA analysis points to domesticated olives appearing in separate places, suggesting that wild olives were in common use and domestication was an attractive option. Oliver presses have been found that are about 4,500 years old.

Most texts state that olives are the oldest known tree crop, having been in managed production since before 3000 BC. Today the focus is on olive oil and table olives, but historically olive oil was used for oil lamps, and as a lubricant and medicine.

The olive tree

The olive tree can be a garden ornament, but it is usually grown commercially for its fruit and for the production of olive oil. There are wild olive trees, and in some parts of the world they are considered as weeds.

Olea europaea is an evergreen tree or shrub, that rarely exceeds 8-10 metres tall, but very occasionally can reach 15 metres. In gardens the trend is to have a single old, gnarled and twisted olive tree, but this is an expensive option because a 100-year old tree can cost more than €1,000. On the other hand, in Spain you can sometimes drive for kilometres and just see young olive trees, row after row after row. A young olive shoot can cost as little as €2.

You can see above that the olive tree usually has upright stems with many branches. The stems are coloured greenish-black to silvery-green, and the older wood has a rough bark that is light to dark grey (young stems are smooth and slightly ribbed).

The olive leaf is oblong, measures between 4-10 cm long and 1-3 cm wide, and has a pointed tip. The upper surface of the leaf is usually glossy dark green and the underside is silvery, greenish, or yellowish-brown. The technical term for their shape is lanceolate, i.e. tapering to a point at the apex and at the base (like a lance tip). In addition, they are attached by a short stalk (so petiolate). The margins (the leaf edge) are called "entire" because they don't have teeth, serrations or lobes, nor is the leaf compound, i.e. they have simple, smooth margins. The leaves are also oppositely arranged, i.e. attached to the stem in pairs that stand opposite each other. If you look carefully at the olive leaf you can see that they are often not flat at the margins, the edges are deflected naturally downwards towards the underside, a shape which is called "recurved".

Wikipedia tells us that the olive tree "has small, white, feathery flowers, with ten-cleft calyx and corolla, two stamens, and bifid stigma, are borne generally on the previous year's wood, in racemes springing from the axils of the leaves". This is going to take some understanding, …

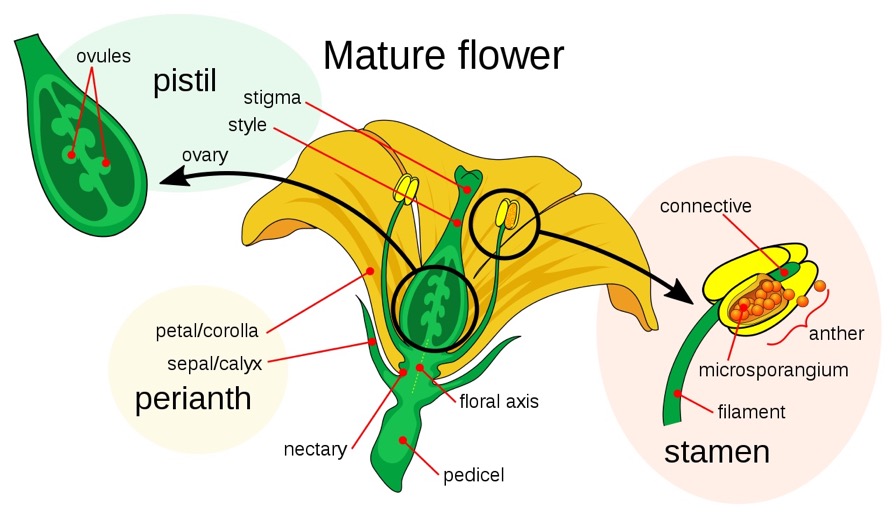

In (no. 1) we can see the flower bud with the corolla (consisting of four petals) still tightly bound together and protected in what is called a calyx, i.e. the green bit which you might think of as the 'husk' or wrapping of the flower. In some cases this wrapping can dry or even wither away, but here it forms what are called sepals (I presume "ten-cleft" means that as it opens it cleaves or splits into 10 parts). Because the calyx is green it's known as sepaloid. The corolla and calyx make up the perianth, or non-reproductive part of the flower. The below diagram from Wikipedia helps…

As our bud blossoms (no. 2) it produces two stamens, and bifid stigma (bifid just means split into two). The stamens are the pollen-producing reproductive organ of the flower. The stigma is just one part of the pistil, which in addition is composed of an enlarged lower portion, the ovary, which encloses the ovules. The basic idea is that pollen lands on the stigma and germinates to grow down through the style to the ovary, and, for each pollen grain, to fertilise one individual ovule. A fruit is the mature, ripened ovary of a flower following double fertilisation. So what this means is that the pollen grain, once it has adhered to the stigma, takes in moisture and begins to germinate, forming a pollen tube that extends down toward the ovary through the style. The tip of the pollen tube then enters the ovary and penetrates the ovule, releasing two sperm. One sperm fertilises the egg cell and the other combines with so-called polar nuclei to form a nutrient-rich tissue which provides nourishment to the developing embryo. The ovary, surrounding the ovules, develops into the fruit, which protects the seeds and in some cases helps disperse them.

The creamy white flowers are borne generally on the previous year's wood, in "racemes springing from the axils of the leaves". What does this mean? If we look at a leaf, its stalk links to its branch at an axil, and we can see the flower stems emerging at the same place.

Now if we look at the flower stem we see that it just breaks up into a series of short flowering stalks, this is called a raceme, i.e. an unbranched, indeterminate type of inflorescence bearing flowers with short floral stalks called pedicels along the axis (shoots coming out from the axil). The pedicel means that each flower has its own stalk.

In fact, flowering and pollination are the most critical stages in olive production. An abundance of flowers is the cornerstone of a good harvest. If you have flowers in June, then that meant that you had buds developed on the growing shoots in April-May of the previous year. The key is flower bud induction, which depends upon the right physiological conditions of nutrients and hormone availability. The right conditions means that the bud tips are there to form the inflorescence axis and flowers. Flower formation and organ development occur from March until May-June, when bloom takes place. The reality is that very few cultivars are capable of pollinating themselves. As a consequence, in an orchard about 10% to 15% of the trees are compatible cultivars that can successfully fertilise the egg cells of the main variety grown. Often more than one polliniser are included in the orchard, and there are tables of the best pollinisers for different cultivars.

And if you thought, like me, that the Wikipedia description was not that accessible, have a look at this entry in the Olive Oil Source.

The olive

The fruit is a small drupe 1.0 to 2.5 cm long when ripe, and containing a single small stone surrounded by oily flesh. You have to be careful and understand that "fruit" just means a seed-bearing structure in flowering plants, so it does not just mean edible sweet fruit. A drupe means an indehiscent fruit with a fleshy part surrounding a single shell with a seed inside. Dehiscence is a splitting, at maturity, along a kind of built-in line of weakness, and indehiscent is when the fruit does not have that preferred line of weakness. This does not refer to a weakness that we might detect, but to a natural way a fruit breaks open to release it contents.

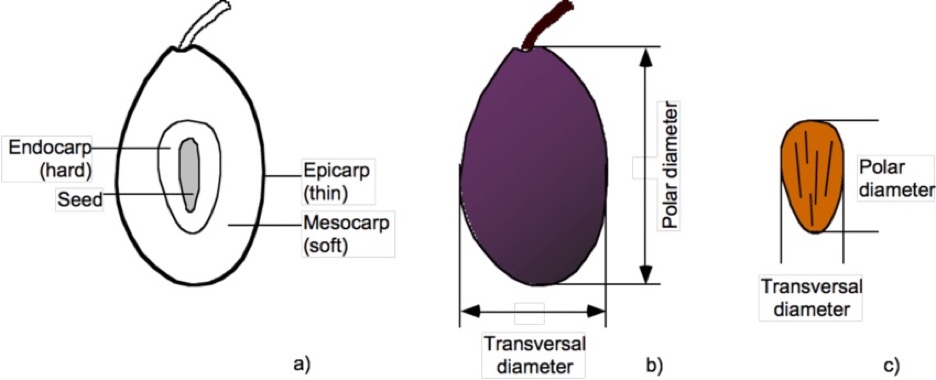

In a) we have the nomenclature of the parts of the olive drupe, in b) its dimensions, and in c) the dimensions of the endocarp. The polar diameter (length) of a Olea europaea europaea ranges from 8.8 mm to 15.1 mm, and the transversal diameter between 6.8 mm and 10.5 mm. The average weight of a mature fresh olive is usually between 3-4 grams. However there are some Spanish varieties that are substantially bigger, for example a Sevillano Gordal can weigh 12 grams.

Olives are harvested in the immature green stage to mature purple-black stage. The stone is a hard brown seed that is usually oblong in shape and about 1 cm long.

Olives are thinner-fleshed and smaller in wild plants than in orchard cultivars.

Flowering plants that produce a drupe (stone fruit) include coffee, mango, date, coconut, cashew, etc., and all members of the genus Prunus (e.g. almond, apricot, cherry, peach, plum, etc.). The unique features of the olive are its bitter component (oleuropein), its low sugar content (2.6-6%) compared to other drupes (12% or more), and its high oil content (12-30%) depending upon the variety and time of year. It is the bitter component that means that most olives cannot be consumed directly from the tree. Oleuropein produces a strong bitter taste, but is not bad for the health. The fruit is usually treated in sodium or potassium hydroxide (both prototypical strong bases), brine (salt solution) or successively rinsed in water to remove the bitterness. There are some olives that will ripen and sweeten on the tree, usually due to a process of fermentation.

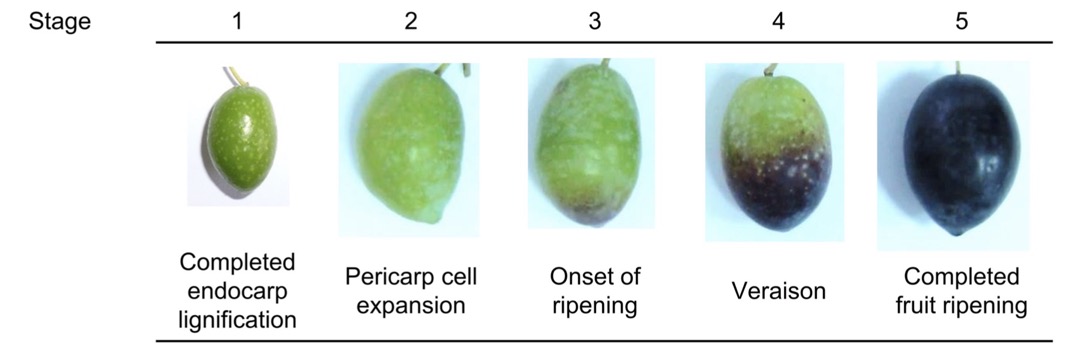

Above we can see the basic phases of development of a Spanish olive (type Picual) grown under irrigation and with fertiliser. The technical measure of time is DPA meaning "days post-anthesis", where anthesis is the period when a flower is fully open and functional (DAF "days after flowering" is also often used). The development of the olive can takes 4-7 months and is usually divided into five or six phases. The first phase is fertilisation and early cell division, promoting embryo growth during the first 30 days after flowering. Next the seed develops with rapid fruit growth, principally of the endocarp (30-60 days). Thirdly, the endocarp hardens and fruit growth slows down (60-90 day). Above we can see the first Picual olive having completed its endocarp lignification (hardening) after 70 DPA. At this point the olive's fresh weight is around 1 gram, its very firm and contains only about 2-3% lipids. Now, the soft flesh (mesocarp) develops and there is a period of intense oil accumulation (90-150 days). Above we can see pericarp cell expansion, the pericarp being the general name for the endocarp (shell of the seed), mesocarp (the flesh), and the exocarp (skin). What we have now is an Picual olive at 125 DPA, which weighs about 3 grams, but remains very firm and contains a limited amount of lipids. Now we enter the phase of ripening, with the fruit changes from dark lime-green to lighter green and purple (after 150 days). Above we can see our Picual olive start to ripen at 168 DPA, it now weighs more than 3.5 grams, is noticeable softer and the lipid content will have risen to about 8%. Above, at 182 DPA we see the visible onset of veraison, or ripening. Our olive is becoming increasingly soft to touch and the lipid content will be about 14%. The last image of our Picual olive is after 210 DPA where it is now fully ripe, weights about 4 grams, is soft to touch and the lipid content could be as much as 19%. Fruit tissue during these phases undergo numerous biochemical and physiological transformations, including cell division and enlargement, oil production, metabolite build-up, mesocarp softening, phenol breakdown, and coloration change owing to anthocyanin accumulation in the outer mesocarp.

So there are three basic types of olive:-

Green olives are obtained from olives harvested during the ripening cycle when they have reached normal size, but prior to colour change. They are usually hand picked when there is a slight change in hue from leaf-green to a slightly yellowish green and when the flesh begins to change consistency but before it turns soft. Colour change should not have begun. Once harvested, the olives are taken to the plant for processing on the same day if possible.

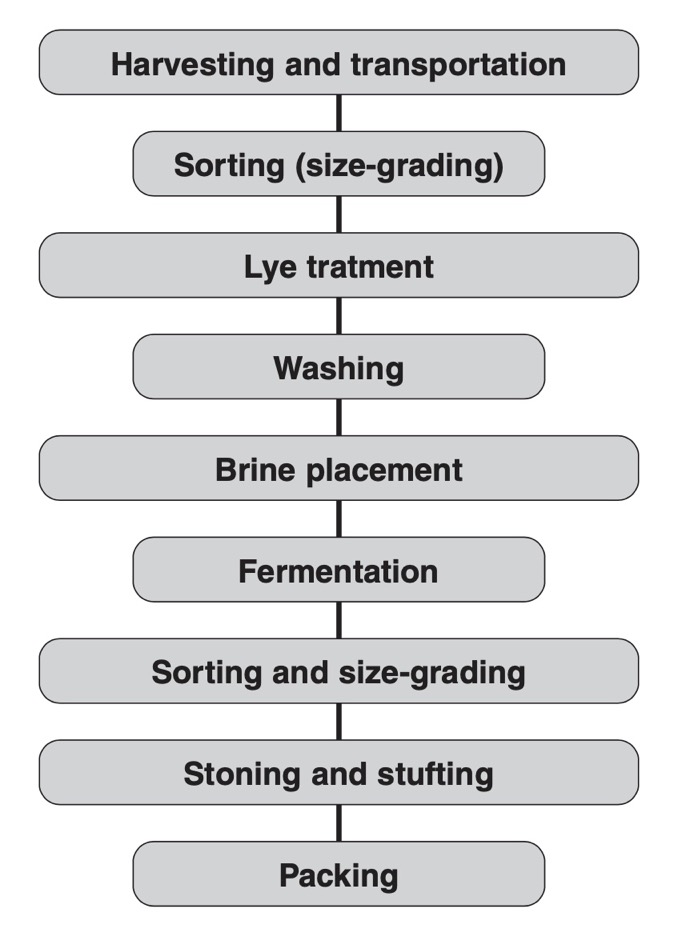

Green olives are processed in two principal ways, either with fermentation (Spanish type) or without fermentation (Picholine or American type). In the Spanish way the olives are treated in a diluted lye solution (sodium hydroxide also known as caustic soda) to eliminate and transform the oleuropein and sugars, to form organic acids that aid in subsequent fermentation, and to increase the permeability of the fruit. The lye concentrations vary from 2% to 3.5%, depending on the ripeness of the olives, the temperature, the variety and the quality of the water. The treatment is performed in containers of varying sizes in which the solution completely covers the fruit. The olives remain in this solution until the lye has penetrated two-thirds of the way through the flesh (6 to 11 hours). The lye is then replaced by water, which removes any remaining residue and the process is repeated. Lengthy washing properly eliminates soda particles but also washes away soluble sugars which are necessary for subsequent fermentation.

Fermentation is carried out in containers in which the olives are again covered with brine. Traditionally, this was done in wooden casks. The brine causes the release of the fruit cell juices, forming a culture medium suitable for fermentation. Brine concentrations are 9-10% to begin with, but rapidly drop to 5% owing to the olive’s higher content of interchangeable water.

At first Gram-negative bacteria multiply, but after a week and a half they disappear. They are a consequence of contamination produced in the plant installations, and depend much on the hygiene measures applied. At a pH level of 6 and upwards, lactobacilli develop massively until the Gram-negatives disappear and the brine attains a pH of 4.5. There is a predominance of Lactobacillus plantarum which produces lactic acid from glucose almost by itself. This particular Lactobacillus is found in many fermented food products. When the fermentable matter is spent, acid formation ceases. There are a number of problems that can occur usually due to the appearance of undesirable microorganisms which can transmit poor organoleptic properties to the olives or impair their storage properties. Generally the key is the hygiene precautions applied when the olives are delivered to the plant, as well as during lye treatment and washing. When properly fermented, olives keep for a long time. If they are in casks, the brine level must be topped up. At the time of shipment, the original brine is replaced and the olives are packed in barrels or tin or glass containers. Sometimes they are stoned (pitted) or stuffed with anchovies, pimiento, etc. The most commonly used varieties are Manzanillo, Gordal, Hojiblanca, and Moroccan Picholine.

As far as I know the lactic acid bacteria founding in olive fermentations are the same kinds as found in cabbage (sauerkraut) and cucumber (pickle) fermentations.

Semi-ripe olives are obtained from olives that are picked when their colour is starting to change. They are harvested before full maturity, when the flesh is quite firm and oil formation has not concluded. The process of darkening the fruit by oxidation is typical of California. Olives suitable for processing as green olives are selected as they enter the factory, then placed in brine at concentrations between 2.5% and 10% in inverse relationship to fruit size, and they are protected from air. The olives are placed in large concrete tanks in an initial solution of 2% lye until they are ready for subsequent preparation. When prepared for the market, they are placed in low-concentration lye and then washed in water into which compressed air is injected. Further treatments in dilute lye, each followed by aeration, facilitate penetration through to the stone. Next, the olives are washed to eliminate lye residue and to lower the pH to close to neutral. Solutions of 0.1% ferrous gluconate or lactate are often applied to enhance fruit darkening (it is E579). After placement in brine for a few days, the olives are ready for canning. Heat processing in the form of temperature and pressure-controlled sterilisation is fundamental to ensure the product keeps properly, but the process is well known and used in much the same way as for other foods.

Ripe olives are harvested when the fruit has attained the colour and oil content corresponding to each particular variety. There are many types of preparations depending on local tastes, however there are two basic preparations, black olives in brine or in dry salt. Black olives in brine are typically found in the eastern Mediterranean countries, particularly Greece and Turkey. The fruit is picked by hand when black ripe, but before the olives over-ripen or are shrivelled by frost. They have to be transported as quickly as possible to the processing plant where they are sorted, washed and immersed in 8-10% brine. At the start of fermentation the tanks are tightly sealed because the olives must not be exposed to air. The brine stimulates the microbial activity for fermentation and reduces the bitterness of the oleuropein. When the bitterness has been sufficiently weakened, the fruit can be sold. The colour fades during the process, but is corrected by aerating the olives for two or three days, although sometimes they are treated with 0.1% ferrous gluconate or lactate to make them a deeper black. Lastly, the olives are selected and packed in barrels or varnished cans, which are filled with 8% fresh brine. They are popular because of their slightly bitter taste and aroma. They can also be packed in vinegar (25% of brine volume) and may even be heat processed, and a few grams of oil are then added to each can to form a surface layer.

Preparation in dry salt is also of Greek origin, and is used with overripe olives of the Megaritiki variety. They are vigorously washed and placed in baskets with alternating layers of dry salt equivalent to 15% of the weight of the olives. The end product is not bitter, but salty, and it looks like a raisin.

Increasingly, olives are eaten after being seasoned with herbs, pieces of orange, lemon, garlic, paprika, oregano, etc. Until the turn of the 20th century, the table olive market tended to be local, but since then the market has expanded to non-producing areas where table olives have become popular. This is particularly true of Spanish, Greek and California olives.

Extracting olive oil

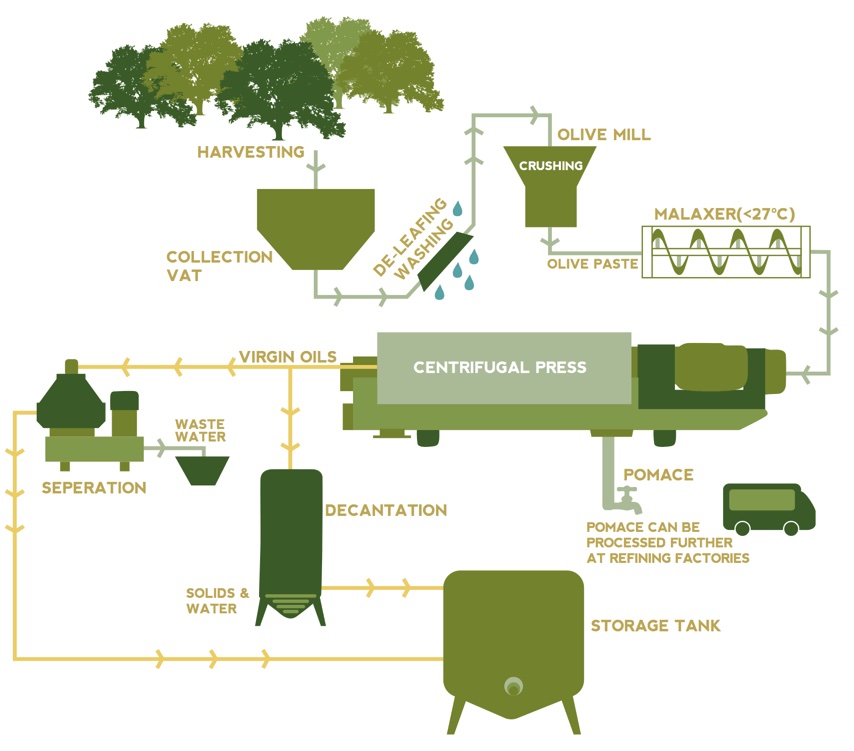

The traditional method for extracting olive oil involved first the hand picking, removal of any remain leaves, and a washing to remove any impurities. As we can see above, today you can use combs and nets, or even tree shakers.

Traditionally the olives were then crushed using two or more granite wheels known as molazze, which were fixed to an axis and rolled around a circular trough. The fruit and kernels were broken down. The molazze and the trough were a few millimetres apart to avoid over crushing the kernels. The resulting paste then underwent a process called malaxation, during which it was stirred continuously with paddles to encourage the oil to form larger droplets, making it easier to separate it from the other liquids in the paste. Then the paste was spread over fibre mats (working as a kind of filtration diaphragm), stacked one above the other. The mats were pressed mechanically and the oil forced out of the paste. What remained was the solid components of the paste, and the oil and water was collected. The liquids were pumped into a centrifuge to separate the oil from the water and other impurities. The process was not technically difficult, but it required lots of manpower. The efficiency of the process depended on keeping the stones and fibre mats clean so that they work properly. In most texts this process is considered obsolete.

In the 1950's and 1960's continuous centrifuge extraction replaced the press. The paste is pumped into a centrifugal extractor (decanter), and in the multiphase extraction process there are three outlets, one for oil, one for water and one for husks. The process can be run in batches so that each batch has an owner.

So the first thing to note is when "mechanical process" is mentioned, they are allowed to use of a centrifuge on the paste. Pressing and centrifugation are both considered mechanical processes. It is true that heating the centrifuge will improve extraction, but will also affect the quality. That's why some mention a "cold mechanical process". Any label that does not explicitly mention "extra virgin olive oil" but uses worlds like "light" or "pure" still means that they are probable refined oils, and of a lower quality. Also expressions such as "first cold press" are doubtful today, simply because most mills use a continuous centrifuge process. And even when "cold press" is on the bottle it is probably not true, but as some experts note, removing it from the label would be economic suicide.

Obviously the optimal harvesting time must be when the oil levels are highest in the fruit, but before natural fruit drop. Transport and storage is non-trivial, because improper handling can provide undesirable enzymatic reactions and the growth of yeast and molds. The aim must be to transport and keep the olives in a well-ventilated, cool, and dry area. Better still if the olives go directly to extraction.

The first step is to clean the fruit, i.e. remove leaf and wash. The first step is deleafing with a strong sucking fan, and the second is washing with running water in a shaking vat with an air injection system to create turbulence in the mass of olives.

The next step is to crush the fruit, with the aim to lacerate all the cells in the fruit. Naturally it's not possible, but the aim to liberate as much oil as possible. Today hammer or toothed-disc crushers are widespread, which are supposed to "gently crush" the olives.

The oil is in the mesocarp cells (simply put, the flesh of the olive) and what is needed is to release the oil from the tissue as droplets that can merge into larger droplets. The olives are crushed with their stone because it contains an antioxidant that acts as a natural preservative. Malaxation increases substantially the yield by enhancing the crushing effect and making a kind of uniform paste. The aim is to break up the oil/water emulsion, and let the oil droplets cling together. The idea is to use different size blades rotating at 15 to 20 revolutions per minute, inside an inert gas to avoid oxidation. Alternatives include endless screws, etc., in all cases the aim is to keep the temperature under 27°C so that they can use the expression "cold extraction".

The next step is about putting pressure on a combined solid/liquid mass. The pressure reduces the volume of the mass and forces the liquids (water and oil) out. This was the basis of the mats and press. This process evolved to the use of powerful hydraulic presses, increasing the pressure over a 40-60 minute period, then maintaining the pressure for 10-20 minutes. This technique extracts about 86-90% of the liquids from the paste, and still maintains a low temperature in the paste. This is a batch process that is manpower intensive. It is still used, but it's no longer widespread.

The modern technique is no longer to press the liquid out of the paste but to suck it out. In principle gravity would over a very long period separate the liquids out of the paste, but the key words are "very long". But using an artificial gravitational force in a rotary machine it possible to rapidly separate liquids from solids, and also separate different liquids based upon their densities. The machines are horizontal centrifuges which create the equivalent of 3000 times our natural gravitational force. The solids, being heavier, are pushed to the rotating wall, and liquids form concentric linear layers depending upon their densities.

Now the challenge is to remove the solid waste to a decanter, allowing the liquids to move forward to a separator. A two-phase decanter separates the solids and liquids, whereas a three-phase decanter separates two different liquids of different densities. It turns out the two-phase decanter has been optimised to separate the oil from a wet olive pomace as a solid.

A final step involves what is called a clarifier (a type of vertical centrifuge), which removes any remaining vegetable water and suspended solids.

We should not forget that olive oil in storage should be kept in the dark and at under 25°C. Also the whole bottling process and transport should be food grade.

The market for olive oil and table olives

As of November 2020 the world olive oil production was forecast to be 3.23 million tons (2020/21). EU production was forecast to be 2.23 million tons, of which Spain would produce 1.60 million tons (then Italy with 0.27 million tons and Greece 0.26 million tons). So Spain produces about 50% of the world's olive oil. Despite an excess production of olive oil the EU still important substantial quantities from Tunisia. However it exports olive oil to the US, Brazil, UK, Japan, China, etc. Oddly, Italy is a major importer of olive oil from Spain, Greece, and Portugal.

As of November 2020 the world table olive market was 3.14 million tons (2020/21). EU production was forecast to be 0.90 million tons, of which Spain would produce 0.59 million tons (Greece was next with 0.23 million tons). So Spain produces about 19% of the world's table olives. The EU imports table olives principally from Morocco and Turkey, and exports them to the US, Russia, UK and Saudi Arabia.

The most recent global overview of the world of olives dates from 2015, and refers back to 2012 as a yardstick. In 2015 there were more than 11 million hectares under cultivation, in 47 countries, although 98% of the world's olives were harvested in the Mediterranean region. In 2012 the production was 3.1 million tons, as compared to a forecast 3.23 million tons for 2020/21. In 2012 there were approximately 12,000 olive oil mills in the world, and the oil was consumed in over 160 countries.

The reality is that the cost of olive production depends upon the number of trees per hectare (usually around 180 trees), which depends upon the slope of the terrain, and the form of water supply, i.e. rain fed or irrigated. More than 60% of the world's olive production still involves traditional rain fed orchards on moderate or steep slopes. Taking everything into consideration the majority of countries fell close to the world average production cost of €2.63/kg for olive oil. Tunisia, Morocco and Turkey were below that, and Algeria, Uruguay, Italy and Israel were substantially higher. The analysis became more complex when they saw that the intensive (unto 800 trees per hectare) and irrigated cultivation had the highest production cost per hectare, but also the highest productivity. But the more traditional and rain fed orchards had higher unit production costs per kg of olives, and ended up being less profitable. The farm represented 84% of the cost, with the remaining 16% going to transportation and processing. Spain had the lowest processing cost at €0.03 per kg, due to the size of their mills. The average of €2.63/kg actually hides two distinct groups, with traditional rain fed olives costing €3.45/kg and olives from the super-intensive production system costing only €2.05/kg.

Jaén is home to the largest area of olive groves in the world. That's 300 million trees over an area of about 2.5 million hectares. They produce between 20% and 25% of the world's olive oil. The Almazara Nuestra Señora del Pilar is the biggest olive mill in the world. In a year they produce something like 20,000 tons of olive oil, that's twice the average annual production of the US. During the harvest they can receive up to 2,200 tons of olives per day, and in a year they can handle nearly 90,000 tons (almost all Picual).

Buying table olives

When you are in Spain you can go to almost any supermarket chain or marketplace and find a stall selling a bewildering variety of table olives. The below presentation looks sophisticated compared to some you might find in local village markets, etc. You just ask for your favourite and they will scoop some into a plastic bag, knot it, weigh them, and take the money.

I suppose the only way to truly understand table olives is to buy a variety and taste them. But in Andalucía I've been told the most popular are as follows:-

Picual – This is the most abundant variety both in Spain and around the world. The name comes from the pointed tip of the olive. I've read that more than 900,000 hectares of this olive are planted throughout Andalucía. This olive is popular because but it has a full, light peppery taste. It is also a very stable oil that doesn’t go rancid easily.

Hojiblanca – This well-loved variety that accounts for around 15% of Andalucía’s total olive crop. It is mainly found in Málaga, Córdoba, Cádiz and Granada. The name “hojiblanca” translates as “white leaf” and this comes from the leaves’ silvery colour that produces a unique sheen in the sunlight. Hojiblanca olives have a very slightly bitter flavour.

Picudo - A popular local variety that produces a fruity oil. The name comes from the pointed-curved tip of the olive.

Lechín de Sevilla – These olives from Seville province. Some texts mention that it produces a fruity oil, and other texts suggest that it is typically mixed in with others to produce blends of olive oil.

Manzanilla Sevillana - This is a popular table olive, produced in Seville province. It has a medium fruitiness and a hint of spice.

Gordal Sevillana - Is a famous table olive because of its larger than normal size, but despite its size it does not yield a high oil content.

Verdial de Vélez-Málaga – This olive is cultivated around Vélez-Málaga in the province of Málaga. It is known as a particularly sweet olive.

I had planned to attach a photograph to each of the above olives, but frankly I could not tell the different between one and another. In addition I found the same photograph professing to be different olives.

Buying olive oil

If you are not standing perplexed in front of a counter full of table olives, then you are in a supermarket looking at a shelf full of bottles of olive oil. The first thing to look at is the difference in classification of the olive oil.

The one you tend to see a lot, is "virgin olive oil". This is obtained from the fruit of the olive tree solely by mechanical or physical means in a way that does not alter the nature of the oil. The olive can undergo washing, decantation, centrifugation and filtration, but solvents or adjuvants having a chemical or biochemical action are not allowed. Also a re-esterification process, or any mixture with oils of other kinds, is not allowed.

If it just says "virgin olive oil" it means that the oil has a maximum free acidity, in terms of oleic acid, of 2 g per 100 g.

If it says "extra virgin olive oil" it means that the virgin olive oil has a maximum free acidity, in terms of oleic acid, of 0.8 g per 100 g.

If it says "Lampante olive oil" it means that the virgin olive oil has a maximum free acidity, in terms of oleic acid, of more than 2 g per 100 g.

If it says "refined olive oil" it means that the olive oil has been obtained by refining virgin olive oil, and has a free acidity content, in terms of oleic acid, of not more that 0.3 g per 100 g.

It can also indicate that an olive oil is composed exclusively of refined olive oil and virgin olive oil, so it's a blend (excluding Lampante olive oil). and has a free acidity content, in terms of oleic acid, of not more that 1 g per 100 g.

The above is according to Annex XVI of Regulation (EC) No. 1234/2007. So it's really a choice between two different types of olive oil, the more natural "extra virgin olive oil" (EVOO) and the "olive oil" (OO) composed by mixing virgin olive oils with refined olive oils. The more exclusive and expensive "extra virgin olive oil" is usually found in the smaller glass bottles, whereas "olive oil" (OO) can often be found in 5 litre plastic containers. There are literally 1,000's of websites that tell you which to use, for what, and why.

So firstly, "virgin olive oil" is extracted by physical processes only, whereas "refined" means that it has been chemical treated to neutralise the strong taste and neutralise the acid content. You can occasionally see mention of Olive-Pomace oil, which is extracted from the pomace, the ground flesh and pits left after the pressing. The process uses a solvent and heating. "Extra virgin olive oil" means that it was obtained by cold extraction, and it cannot contain any refined oils. "Virgin olive oil" also cannot contain refined oils, but the acidity is higher that with "extra virgin olive oil". Then you see simple "olive oil" this is usually a blended oil including refined oil. Olive-Pomace oil cannot be called olive oil. Lampante olive oil is not used for consumption, because it has a high acidity and strong organoleptic defects.

We need to clarify some points in above texts. About 98-99% of olive oil by total weight are triglycerides, which are the simplest lipids formed by fatty acids. As you might guess from the name a triglyceride is a natural ester derived from a glycerol molecule and three fatty acid molecules, and is the main constituent of vegetable fat (it's also the most common type of fat in the human body). Triglycerides are the major energy reserve for both plants and animals. The remaining part of the olive oil consists of more than 230 chemical compounds such as alcohols, sterols, hydrocarbons, volatiles, and antioxidants. The fatty acid composition of olive oil varies widely depending on the cultivar, maturity of the fruit, altitude, climate, etc. The major fatty acid in olive oil is oleic acid, a monounsaturated omega-9 fatty acid. It makes up 55% to 83% of olive oil. Linoleic acid, a polyunsaturated omega-6 fatty acid makes up between 3.5% and 21% of olive oil. The rest is usually made up of small quantities of polyunsaturated Linolenic acid (0-1.5%), and palmitic acid (7.5% to 20%) and stearic acid (0.5% to 5%), both saturated acids. So a triglyceride could be palmitic-oleic-oleic (POO) etc., or any other combination of three fatty acids. As we can see olive oil contains more oleic acid than other vegetable oils, and thus is more monounsaturated.

However, the bonds between the fatty acids are delicate, and they will breakdown easily by light, heat, etc. The "acidity" in olive oil is the degree of breakdown of the triglycerides, where free fatty acids are created. The "acidity" levels were mention in the definitions of different qualities of olive oil, but what does acidity really mean? Firstly we saw that the lower the acidity, the better the quality of the olive oil. So what the acidity level measures is the amount of free fatty oleic acid, the most abundant in the olive cells. The percentage given is the weight of free oleic acid to the total amount of olive oil. Logically it should be written as (%) but it's often expressed as degrees (°).

People confuse olive oil acidity with the intensity of the flavour of the oil. Evidence shows that triglycerides don't stimulate a taste, although clearly they can carry flavour compounds and alter texture. It is true that acetic acid, structurally also a fatty acid, does taste of vinegar, but tests have shown that the fatty acids found in olive oil don't have an identifiable taste in the sense of sweet, salty, acid (sour) and bitter. So you can't taste the acidity of olive oil. There is some confusion since an olive oil will have a certain taste and acidity, and we can see that the best "extra virgin olive oil" must have a maximum free acidity, in terms of oleic acid, of 0.8 g per 100 g. We will learn below that high acidity is a sign of poorer quality, and this is why it goes for refining, which reduced its acidity and flavour. And this is also why when some high acidity oils are mixed with very low acidity refined oils, they must be marked "blended". But you also saw that any olive oil with acidity of about 2% must be classified as Lampante olive oil, and cannot be used in blended oil.

Sometime ago the acidity levels was a major claim as to an oils quality. Consumers were confused and the legislation was changed. If an acidity is mentioned producers must also mention the index of peroxides, waxes, and the ultraviolet absorbances. Producers shifted to rating their olive oil soft to intense. So today only very high-end producers (read very expensive) put the acidity level and other values on their labels.

Acidity increases when the olives or oils are exposed to oxidants and aggressive environments. Initially the triglycerides are protected from oxygen inside the olive fruit on the tree. If the skin is broken, the oxygen gets into the fruit and starts to breakdown the triglycerides and the acidity rises. Skin can be bitten by insects, damaged by hailstones or by falling on the ground, bruised during the harvesting or transport, etc. Olives are often packed waiting to be crushed, and the weight can itself start to crush the ones on the bottom. Acidity will rise quickly and may even start the fermentation process. This is all the more true for the more mature, softer olives.

This is also why during the grinding and production process they try to limited the exposure to air and control the temperature, remembering that the higher the temperature, the faster the oxidation reactions (and higher the acidity). This is also why here and there its mentioned full tanks, or watertight lids, or inert atmospheres, etc.

So in many ways the acidity is a measure of the care taken right from blossoming and fruit set, though harvesting and extraction, to the eventual sale and consumption of the oil.

The colour of olive oil can vary from a light gold to a rich green. Green olives produce a green oil because of the high chlorophyll content. Ripe olives yield a yellow oil because of the carotenoid (yellow red) pigments. The exact combination and proportions of pigments determine the final colour of the oil.

How do you know your olive oil is good? This is technically called an organoleptic assessment, and is dependent upon the fatty acid composition and the presence of minor compounds including volatile and phenolic compounds. The majority of the olive aroma derives from enzymatic oxidation of the fatty acids, linoleic and linolenic. For example, if the oil smells fragrant and pleasant its probably due to the presence of butanone, and if it has a green, pungent smell it may be due to butyl acetate. The biggest source of variety is flavour is the olive cultivar, followed by the ripening state at which the olives were harvested. Other factors that can affect different organoleptic characteristics (good and bad) include soil salinity, climate/region, fertilisation and irrigation, harvesting system, and the oil extraction system. For example, people find that olive oil extracted using a stone crusher is more aromatic.

Negatives include:-

A fusty or earthy taste (i.e. slightly fermented or yeasty)

Winey or vinegary taste

Acid or sour

Rancid (intense oxidation)

Thick, pasty taste

Greasy

Brine

Metallic

Cucumber (comes from oil that has bee n packed in tin containers for too long).

Positives include:-

Fruity, as with green fruitiness, ripe fruitiness, delicate fruitiness (can be smelt as well)

Bitter as with delicate bitterness, etc. (primary taste of oil from green olives)

Pungent (from unripe olives).

These positive attributes can be defined on the bottle, as having an intensity that is robust, medium or delicate. The term "well balanced" should mean that the bitter/pungent attributes are slightly stronger that the fruitiness. Mild means bitter/pungent attributes are low.

Generally an "extra virgin olive oil" (EVOO) should be:-

Well balanced

Medium fruitiness

Light on bitterness and pungency.

Some experts have added "harmony", "complexity" and "persistency"

Owning a decorative olive tree

Olive trees grow best in Mediterranean-like climates, but they will start to suffer if temperatures drop below 0°C for any length of time. So they do well in warm climates, are tolerant to drought, but are sensitive to frost. Ideally they like mild winters and long, warm, and dry summers. They like the sun, and fruit production can be affected if they spend long periods in the shade.

Everyone suggests that you buy an olive tree from a local grower, and you can buy one in a pot, or for planting in a garden. Prices can range from a few € for a young shoot, to over €1,000 for a 100-year old mature olive tree. For larger trees the shipping and placement is as important as the tree itself.

There are the usual constraints about planting any tree that eventually will become quite large. Olive trees can reach 10 metres tall, and have a span of more than 10 metres. The roots can interfere with sewers, piping, cables, etc., and a mature tree can caste quite a shade, including over a neighbours garden.

Small or young olive trees create very little shade. Also young olive trees grow quite slowly, probably 10-20 cm growth per year, and the first fruit will appear after 5-7 years. You can expect full fruit production after 15-20 years. Growth can be significantly more if the tree is planted in a shaded area, since it will spread out to try and capture as much sunlight as possible. If planted in a sunny plot it will grow less, and adopt a more compact, bushy structure with thicker branches and leaf structure. Olive tree like well-drained loamy soil with a mix or sand, silt or even clay. Mature olive trees are remarkable resistant, and can be completely cut back, dug up and moved, and they will survive and adapt to their new surrounding quite quickly.

Olive trees can live quite comfortable with a rainfall of between 80 and 300 cm per year, but below 80 cm per year they will need some form of irrigation otherwise fruit production will be affected. An olive tree can survive on about 5 cm of rain per month, i.e. about 60 cm per year.

One problem often ignored is that when the fruit falls, it can be messy and stain terrace surfaces, etc.

Owning and looking after an olive grove

The story goes that you may have some land with some old olive trees that have already died from decay, frost or pests. Or the soil may be poor, and make it difficult to deliver water, oxygen or fertiliser/nutrients to the roots. Perhaps the variety of olive tree is no longer accepted in that particular area, and would not receive a PDO "protected designation of origin" or PGI "protected geographical indication".

A new olive orchard might be economically interesting, and it might be a cheap option for the land available. Young olive trees are easy to find, and they grow quickly and start bearing early. The key to being a cost-effective option is high yields and economical cultural practices. For large olive farms that means the intense use of machinery, particularly for harvesting.

You hear a lot of stories of people buying an early retirement home in Spain with a small number of olive trees, but not knowing what to do with them. You also hear stories about an olive tree orchard earning €15,000 or €20,000 annually "and you don't have to do a thing".

The EU oil market is best represented by prices in Bari (Italy), Chania (Greece), and Jaén (Spain). For April 2020, extra virgin olive oil in Jaén was at €206 per 100kg, and by May it had dropped to €200 per 100kg, and in July it dropped as low as €178 per 100kg, before starting to rise again. The problem is that for Jaén, prices were over €400 per 100kg in 2015/2016, and were nearly €400 per 100kg in mid-2017, before dropping below €200 per 100kg now (2020). Prices are even lower for Lampante olive oil, refined olive oil and simple virgin olive oil.

Firstly, the land needs weeding, and olive trees need pruning and protecting against fungus, infections and insects. They may need fertilisers, and they almost certainly will need some form of seasonal irrigation. Then there is the harvesting. The local cooperative may do this work, but they will take 75% of any revenue (as would any outside contractor), and you might just get back your part in olive oil.

A mature olive tree will produce between 15 and 40 kg of olives. On average you need about 5 kg of olives for one litre of oil, but everything depends on the type of olive and its oil content. So one tree might produce between three and eight litres of olive oil. So to earn €20,000 you will need between 1,500 and 3,500 mature olive trees, that means between 10 and 25 hectares (100,000 to 250,000 square metres).

So looking after 1,000's of trees is not "money for nothing".

The key to a healthy productive olive tree is the proper management of the root activity, carbohydrate synthesis, flower bud differentiation and fruit development.

An adult olive tree will concentrate its roots down to a depth of about 60-80 cm, and it will focus on any wet soil zones, for example near drip systems. The root system will spread out more in clayey soil that holds moisture, and also the roots will go deeper if the tree is on a hand imperious calcareous pan that prevent deep drainage.

A young olive tree will first develop fine roots in the initial 20 cm of soil, then it will start to send larger roots deeper into the soil, each time adding more fine roots. Most roots are located in the first 60 cm of soil, but they can go down to 1 metre. Initially the root volume will expand quite rapidly, and a 3-year old tree could have a root volume of more than 3 cubic metres, expanding at about 1 cubic metre per year. A 5-year old tree will occupy about 50% of the root volume of a mature tree. Roots at all depths, are far less frequent outside the canopy of the tree, and the root volume and canopy are closely related. One amazing fact is that a 1-year old olive tree will have a total root length in excess of 1 kilometre, and a 5-year old will have a total root length in excess of 7 kilometres. It is in the 6th year that the olive tree really become established. As compared to a 5-year old tree the root volume will double and the root density will triple, meaning that the total root length will go from about 7 kilometres to more than 30 kilometres.

A 6-year old mature olive tree will have a canopy that has grown to about 10-12 square metres, with about 2.3 kilometres of leaves per square metre, whereas the surface occupied by the roots can be expected to be around 12-14 square metres. Data shows that root volumes can be about ⅓ smaller for rain fed trees as compare to drip fed. One key finding was that drip feeding during the dry season meant that the roots continued to grow and prevented shrinkage. Also it was interesting that the tree finds an equilibrium between root and canopy development after 4-5 years.

As the tree matures and with the first-fruit, the tree has to re-orientate the way it mobilises carbohydrates, i.e. growing olive rather than growing roots and shoots. Given adequate watering, it appears that the tree adjusts their root development to the winter period when there is low competition with shoots and fruit development. An important consideration for a young orchard is that only a small fraction of the rainfall water is accessible to the trees, and if irrigation is envisaged then it should be based upon a model of how the root and canopy develop together, i.e. determine the amount of local irrigation needed as a function of the canopy size.

In Europe inflorescence (flower clustering) starts in March, and flowering occurs in June, during this period a plant will grow new shoots of about 25 cm long. Growth might continue if irrigated, but is likely to stop if rain fed. Oil will start to accumulated in the olives in the period September-December. Experts tell us that fruit harvesting should start in the middle of November in order to obtain the highest oil yield and avoid natural fruit drop. This is when there are no green olives left on the tree, and oil biosynthesis has ceased.

Carbohydrate synthesis occurs in the leaves at an optimal temperature of 20-30°C and with a particular minimum light intensity (thus the need to avoid leaves developing in the shade). Given the way leaves are often not optimally oriented, its vital to avoid leaves shaded in the canopy (or by adjacent trees). Photosynthesis is limited by moisture and heat stress (so-called abiotic stress), and by attacks from pests and diseases (biotic stress). Soil moisture content is particularly important for olive leaf photosynthesis, however the relationship is not linear and soil moisture level of of between 4% and 10% are often encountered in practice. Plant tissues use part of the assimilates for annual growth (roots and shoots) and respiration, while the rest goes straight to organs like fruits. To best understand this the living tissue in vascular plants, the phloem, transports the soluble organic compounds made during photosynthesis (called photosynthates), in particular sugar sucrose, to parts of the plant where needed. So photosynthesis transforms carbon dioxide and water into sugars and assimilates, with the help fo sunlight. The sugars are used as building blocks for plant tissue production and to make new cells. The energy needed for this is also indirectly supplied by the sugars. The assimilates have two roles, building material and fuel for plant growth. The plant needs enough assimilates, but a shortage affects things like the development or quality of the buds, flowers, seeds, olives, etc. In highly simplistic terms, leaves are a source and the rest of the plant is a sink (or sinks). Mature leaves that don't get enough sunlight because they are overgrown by younger leaves become sinks. Roots are sinks, and with expand quickly if they receive ample assimilates, or die if they don't get enough. The level of assimilates depends upon the area of leaves (source size) and the amount of light that penetrates through the canopy. Optimal conditions for using the available light is where the surface area of the leaves is about three times the cross-section of the canopy. Ideally the canopy should be relatively open and the sunlight constant over a long period of time, or diffuse.

It is vital to understand that flower bud differentiation, fruit set (seed development) and fruit growth are simulated by the photosynthetic activity of the canopy, and are inhibited by leaf shade.

Pruning has always been key since it accounts for 10-20% of the total effort, but today there are numerous other constraints. The two modern drivers are improving the quality and reducing dramatically the labour needs. Tree shakers are used for harvesting, but trees need to be medium sized with a trunk at least 1 metre high and a canopy without drooping branches. There is an optimal canopy size and volume, and the crop must be concentrated in the middle-upper part. The land should no longer slope too much, and there should be enough space between trees. Tillage, fertilisation and irrigation must be easy and cost effective.

You need the right canopy so that the tree gets the right moisture and nutrient resources made available to it through the soil, climate and fertilisation/irrigation. Tree volume is all about leaf density, which is closely related to area rainfall/irrigation. And the aim is to have the optimum canopy volume for a particular rainfall/irrigation over a particular surface area (measured in tree volume per hectare). In places were rainfall is 'comfortable' the canopy volume can be 3-4 time more than in place with very low rainfall. Canopies can be 20-25% bigger with irrigation.

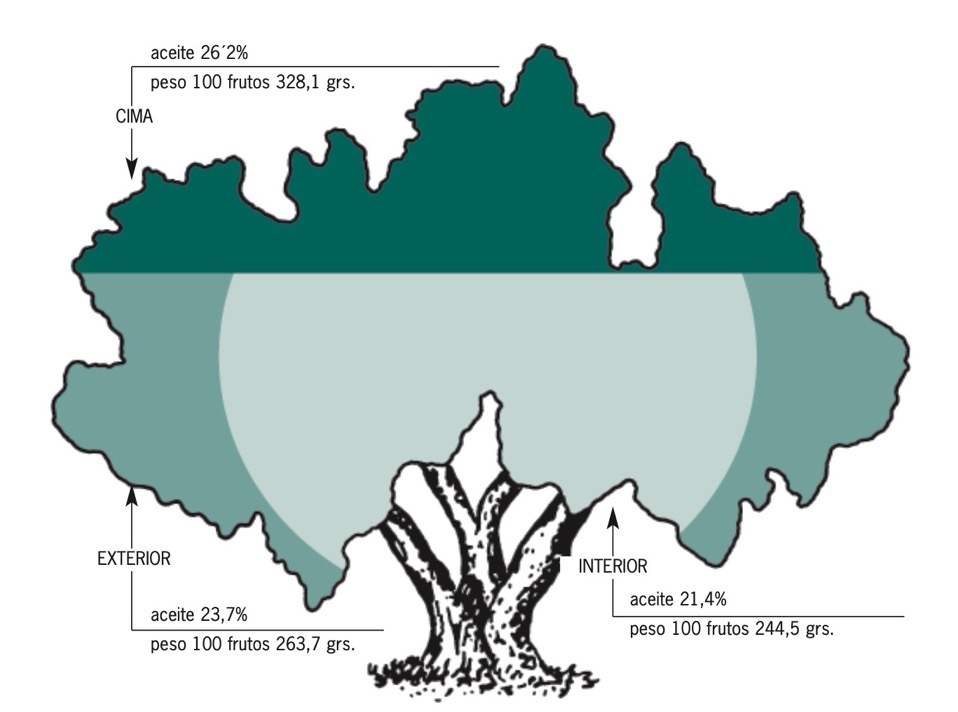

Although in Spanish, the information is self-explanatory. You need to optimise the upper portion of the tree because the olives are bigger and contain more oil. You need to open up the interior of the tree because that's where the olives are smaller and contain less oil. I'm told that there is a Spanish saying that a bird should be able to fly through the centre of an olive tree.

We can see that pruning has become both an art and a science. Each variety of olive tree must be allowed to develop the optimal canopy according to it genetic characteristics, and the soil and climate. Pruning is all about electing the most efficient branches and to correct and preserve the shape without affecting the productive balance of the tree.

Canopy volume is one thing, but what does it mean in terms of surface area and height. The key again is to intercept the maximum amount of radiant energy. In Southern Europe this means for an olive tree, a maximum surface area of about 15 square metres (diameter of about 4.5 metres) and a height of about 3.5 metres. Ideally the leaf density should be about 1.6 to 2 square metres of leaves per 1 cubic meter of canopy.

Ideally the type of olive tree corresponds exactly to the environment (e.g cold resistant, lime tolerance, salinity tolerance, tolerance to common pests, etc.) and the desire for what product and quality level (oil, table olives).

As with anything, often the key is to prepare well the basics. For example, the ground of a future orchard must be properly prepared. Cleaning the land of previous crops, etc. and levelling to make maintenance easy is the first step. Top soil (so-called active soil layer) is precious and should be kept and then re-spread on top. This will ensure that the orchard trees develop uniformly. Irrigation is often mentioned, but before that drainage is also important. Olives are very sensitive to water logging, and to the virulent fungal attacks that go with it and cause root rot. Clay and hardpan layers can easily cause water to collect naturally, and those areas may remain wet and affect the root system of the trees. Also deep tillage (down to 1 metres) is another essential, since it ensures that the roots will not just spread over the surface. Deep tillage on impervious layers is vital to improve aeration and particle structure, and it can include manuring as well. Often an herbicide is applied to kill off weeds. This is particular important if young olive shoots are planted. Also plastic sheet is used to control weeds around plants, and to better control the moisture and temperature conditions of the roots. They say that irrigation is also important in the first two years to ensure that the plants send out roots into the deep-tilled layers of soil. Also it vital to already ensure that the canopy develops properly, so pruning is important even in the first year (removing any strong shoots from the trunk).

Having mentioned pruning, let's continue on that topic. Pruning is necessary for the tree to produce early and regular fruiting, and when pruning is mentioned we should always include the word "training". The key is to remember that the leaves synthesise the assimilates which provide food for all the plant functions. So you need to leave enough shoots so that they will form an adequate leaf area. Leaves are very efficient if the sunlight is direct on the leaf surface, but they may not be even self-sufficient if they are in heavily shaded areas of the canopy (i.e. they become "sinks", and will draw resources to survive). Pruning can heighten photosynthesis by increasing individual leaf area, mesophyll thickness and chlorophyll and by enhanced daily activity because available water is used economically. So it's just as important to ensure soil fertility and moisture availability.

Removing part of the canopy, pruning reduced the number of buds, but the remaining shoots will be more vigorous because they will take up more hormones, nutrients and water from the root system. Too many new shoots will delete carbohydrates stored in the structural part of the tree. Pruned trees start to build up starch later that non-pruned trees, but they have the same level of nutrients at the end of the summer. Also heavy pruning of the whole canopy causes vigorous shoots to develop, and light pruning leads to the development of weaker shoots. Care should be taken in pruning heavily a tree that in the past has not been pruned or has only been lightly pruned. A heavy pruning can actually weaken the whole tree. Pruning of young trees will reduce their crop even further, but it will stimulate vegetative growth. Pruning of mature trees will enhance shoot vigour, encourage flower formation and increase fruit set and development.

The tree is trying the balance the nutrient requirements for flowers, fruit, shoot growth, and its need to build up reserves. Fruit will first reduce root growth, then shoot growth, then tree reserves and finally bud differentiation. The presence of over-vigorous shoots will impede flower bud differentiation because they monopolise synthesised nutrients.

Ideally moderate negative activity should be encouraged during spring growth and the attenuated to make way for the build-up of reserves, fruit growth and flower bud differentiation. Moderate pruning does this, because its effect is limited in time, and allows the the to build up carbohydrates, to supply the fruits with nutrient and to differentiate the flower buds.

There are other aspects to pruning, namely:-

Thinning of branches that are exhausted or hinder light penetration to the interior of the canopy. A branch that has been weakened by fruit production can be pruned back to a new vigorous shoot.

One year old shoots can be cut back, thinning out an overcrowded canopy, and giving other shoots the opportunity to grow.

Removing branches that hang down under the canopy.

Coppicing of parts of a tree that have been damage by frost or fire.

Topping is removing the scaffold branches to rejuvenate the ailing canopy.

Removing dead wood.

And there is the aspect of pruning to train a young tree to its definitive shape.

Pruning can be light, medium or heavy, and can be every year, every two years, three years or even every four years. Clearly the longer you wait the heavier the pruning. According to the experts pruning every three years always produces the best crop production. And light pruning every three years is best.

We have focussed a bit on pruning because it offers an insight into the way olive trees evolve over time, and the logic related to fruit production. However there are many other aspects to running an effective olive orchard, namely:-

Soil management (soil erosion, weeds, adding organic matter, watering, avoiding root injury)

Herbicides

Fertilisation (nutrients such as nitrogen, potassium, iron, boron, calcium)

Irrigation

Plant health (bird control, pests, disease)

Harvesting.